Magnetic Level Gauge- LLI73

The magnetic level gauge is a suitable tool for measuring and monitoring the liquid level of open and pressurized tanks. Due to the special design of LLI73 series magnetic level meters, they are suitable for use in many services (toxic, harmful, flammable, hot, cold, etc.). The LLI73 easily connects to a tank through its connectors.

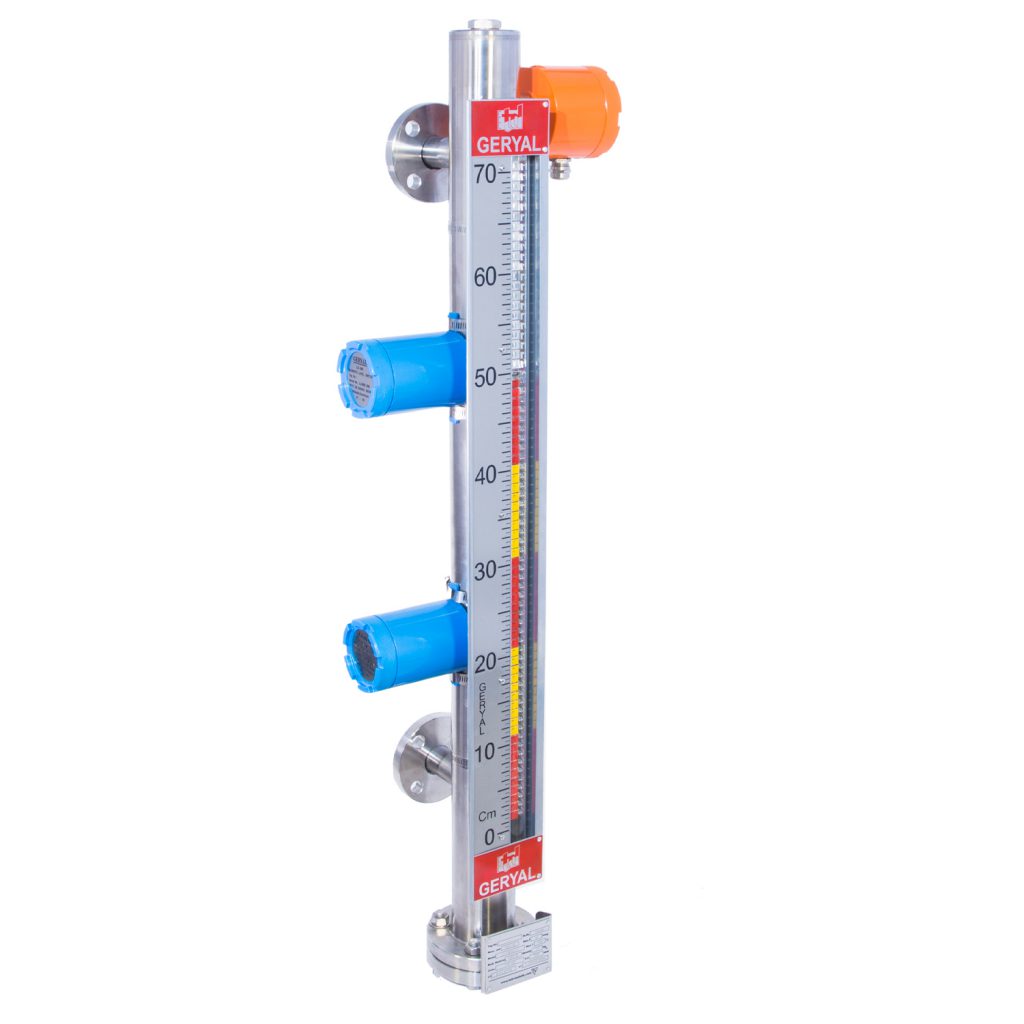

The LLI73 gauge consists of a body or column with a float with a permanent magnet inside. The float is placed on the surface of the liquid and goes up and down with it. The magnetic field inside the float is coupled to the magnetic field of the indicator magnet and moves it. The inductor is mounted on the body and has no contact with process fluid.

In order to control the level of liquids in the processes, control devices such as switches and magnetic transmitters can be easily used on LLI73.

- Suitable for a variety of liquids (corrosive, particles, viscose …)

- Can be manufactured with a variety of materials compatible with fluids. (All types of Stainless Steel, Super alloys, Polymers, Monel, Hastalloy, Titanium and Stainless Steel with PTFE lining)

- Operating Pressure: Full vacuum to 300 barg

- Operating Temperature: -200°C to + 500˚ C

- Wide range of density 35 to 1.8

- High accuracy

- Possibility to install level controllers such as switches and transmitters

- Magnetic limit switches with different capacities for normal and explosion-proof applications

- Transmitter with different accuracy for normal and explosion-proof applications

- Usable in many process

- Can be installed on a variety of reservoirs

- The definitive substitute for sight glass in the boilers, hot water, steam, hot oil tanks, Deaerator, condensate source, fuel source and pressure vessel

- Simple connection by flanges to the tank and boiler

- Full safety because of the lack of liquid and vapor contents with the window glass

- Clear reading of the liquid level even at a distance of 20 meters due to the exact magnetic ruler

- Long lifetime and durability

- Acid Tank

- Boilers (Steam Drums, Boilers)

- Tanks with two-phase liquids (Interface Application)

- Condensers

- Separators

- Cold Services

- Liquid Natural Gas

- many more

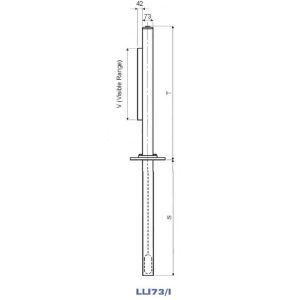

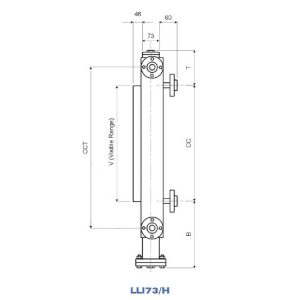

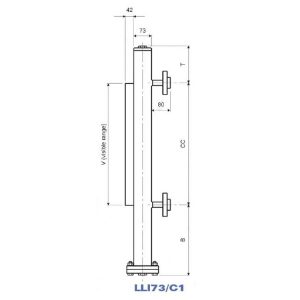

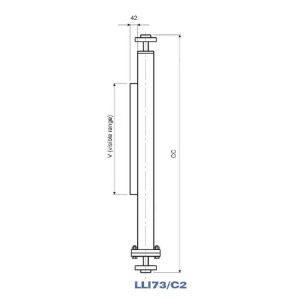

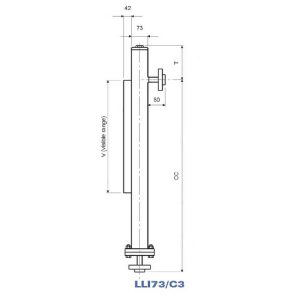

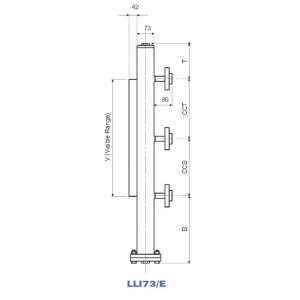

C1:Side-side connecting flange C2:Top-bottom connecting flange C3: Side-bottom connecting flange

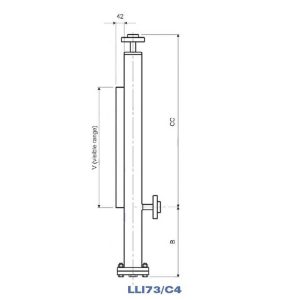

C4: Top-side connecting flange E: Side-mounting dual level indication

I:Top mounting H:Liquid level indicator with heating/coolin jacket