Float and Tape Level Gauge- LLI48

The functional principle of flaot and tape is based on a sophisticated but simple mechanism.

The liquid level is detected by a float that is connected to a very precisely perforated stainless steel measuring tape.

The tape runs from the float and is convolute around a simple machine wheel within the Indicator.

As the tape moves in and out of the Indicator, it tensioned by the spring motor.

When the liquid level changes, the change in the float buoyancy is detected and the spring motor adjusts the measuring tape to maintain the float position on the surface of the liquid.

The measuring tape has a series of holes set at regular interval.

As the tape rotates the sprocket, it activates the display indicator.

The position of the measuring tape holes on the sprocket compensates for the tape weight and prevents the tape from slipping.

Remote reading is added by simply including a transmitter in the counter housing cover

- Usability for long lengths

- Usability for tanks with concrete walls

- Indicator clarity

- High accuracy

- Safe

- No maintenance or very low maintenance required

- Simple and easy installation

- Usable in various process conditions

- Long lifespan

- concrete tanks

- Acid Tank

- Steam Drums, Boilers

- Interface Application

- condensers

- Separators

- Cold Services

- Liquid Natural Gas

- …

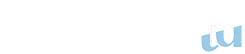

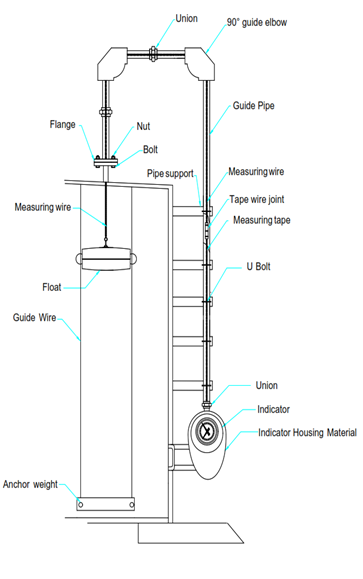

a) Side Mounted

b) Top Mounted

c) Scale Board